More than half of a car is constructed from steel – and little will change about that in the future. “There is no getting around the fact that the automotive industry will have to significantly reduce the environmental footprint of its vehicle production in the future. One solution for climate-neutral production lies in the installation of carbon-reduced steel,” says Stefan Rauber, Chairman of the Board of Management of SHS – Stahl-Holding-Saar GmbH & Co. KGaA and Chairman of the Management Board of Aktien-Gesellschaft der Dillinger Hüttenwerke and Saarstahl AG.

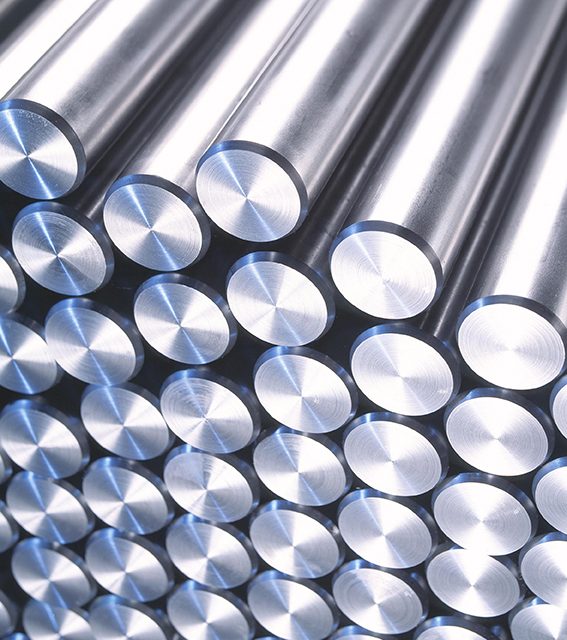

“This environmentally friendly steel is already increasingly in demand by the automotive industry,” reports Peter Schiestel, Head of Marketing at Saarstahl AG. As the world’s leading premium manufacturer of wire rod and bar steel, the company therefore offers this highly sought product in its portfolio via Saarstahl Ascoval. The French subsidiary of the Saarstahl/SHS Group produces its climate-friendly steel in an electric arc furnace at the site in Saint Saulve.

Another fact makes this plant interesting for the automotive industry: the company recently received certification of compliance with IATF 16949 2016, the internationally binding standard for quality management systems for the entire automotive industry supply chain.

Saarland’s steel industry also plans to produce green steel itself

SHS – Stahl-Holding-Saar and its subsidiaries Dillinger, Saarstahl and ROGESA, are also planning to produce up to 3.5 million tons of carbon-reduced steel per year starting in 2027/2028. Following the European Commission’s approval last December of Germany’s EUR 2.6 billion aid measure to transform Saarland’s steel industry, conversion of the plants in Dillingen and Völklingen has now entered the launch phase.

To enable carbon emissions to be cut by 55 percent by as early as 2030, the first step will be to convert up to 70 percent of production to a climate-friendly process.

“With the electric steel plant in France and the planned investments in Saarland, we can fully meet the increasing requirements placed on the carbon footprint of our products,” explains Peter Schiestel.

“Pioneer in green steel production in Germany and Europe”

Up to 4.9 million tons of carbon-reduced crude steel will ultimately be produced in Saarland each year, according to current planning.

“We are pioneering green steel production in Germany and Europe with our ambitious project,” Stefan Rauber emphasized. “What we are implementing is not only a victory for climate protection but also first-class news for our customers.”

| Info box

Saarstahl is one of the world’s leading manufacturers of premium wire rod and bar steel for the automotive and construction industries as well as for general mechanical engineering. The automotive industry is the company’s main customer sector, accounting for around two thirds of total sales. Saarstahl is part of SHS – Stahl-Holding-Saar GmbH & Co. KGaA, along with its sister company Dillinger, a leading global manufacturer of heavy steel plate for steel construction, mechanical engineering, offshore, offshore wind power, and line pipe applications. For more information: www.saarstahl.de |

Photos: © SHS – Stahl-Holding-Saar GmbH & Co. KGaA

– Saarstahl is one of the world’s leading manufacturers of premium wire rod and bar steel (on the photo) for the automotive industry.

– Stefan Rauber, Chairman of the Board of Management of SHS – Stahl-Holding-Saar GmbH & Co. KGaA and Chairman of the Management Board of Aktien-Gesellschaft der Dillinger Hüttenwerke and Saarstahl AG.