The rapid development of artificial intelligence (AI) has revolutionized the business world by providing impressive opportunities to increase productivity.

The Federal Network Agency estimates that AI can increase Germany’s gross domestic product by 11% by 2023, while the European Commission forecasts growth of almost 20% for the European economy over the same period.1

To this day, indirect quality management systems such as machine and process capability are still used in production processes. These statistical procedures often go hand in hand with manual visual inspections at the end of the value chain. Meaningful documentation of the subjective decision rarely takes place, so that neither traceability nor digital verification of the component is possible.

In times where innovation is the key to success, K|Lens its AI technologies, is opening new horizons for more efficient processes and progressive ways of working. The productivity increases are achieved through the sensible combination of two essential factors. On the one hand, defect catalogues and classifications are objectively evaluated, which leads to less pseudo-scrap, and on the other hand, personnel are no longer required for fully automated quality improvement.

Automated end-of-line inspections also often have lower operating costs than manual visual inspections. Sufficient data is also recorded to store complete documentation of the component, the Digital Twin.

The use of Digital twins is becoming increasingly important. Digital Twins are digital representations of physical objects or processes that allow companies to perform realistic simulations and analyses.

Digital Twins enable retrospective simulations of potential risks through a fully documented point cloud. This is an important tool for fending off unjustified claims, especially when it comes to defending against defect and warranty costs.

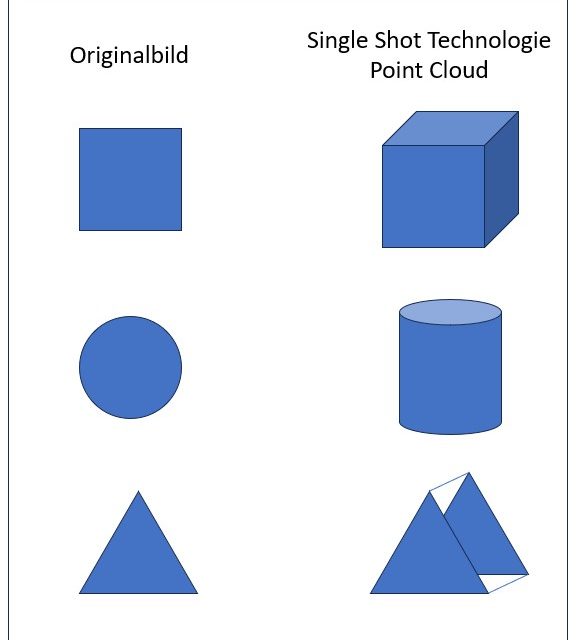

The K|Lens “Single Shot Technology” makes it possible to create 3D models from the point cloud and thus provide a realistic Digital Twin. At the same time, the “Single Shot Technology” can also be integrated into dynamic manufacturing processes, as a single image is sufficient for the entire data acquisition.

The implementation of Digital Twins requires a comprehensive integration of advanced digital technologies and precise data analysis in existing production processes. A key aspect of the security and effectiveness of this data analysis lies in data quality. In this context, K|Lens has repeatedly shown that data acquisition requires deep expertise in image production and hardware design.

K|Lens data analysis, relies on customized neural networks that are developed in-house to meet the specific requirements of each process. K|Lens’ artificial intelligence (AI), which combines the latest technologies and developments as Multiview AI, uses the same data as the Digital Twin itself. This innovative approach not only makes the Digital Twin intelligent, but also enables it to be used both in quality assurance during production and for subsequent digital inspections.

The advantages in terms of efficiency, cost reduction and quality improvement make the use of Digital Twins in conjunction with artificial intelligence an essential element for modern companies aiming for long-term success and competitiveness.

1 www.bundesnetzagentur.de/DE/Fachthemen/Digitalisierung/Technologien/KI/; Accessed on: 21.01.2024